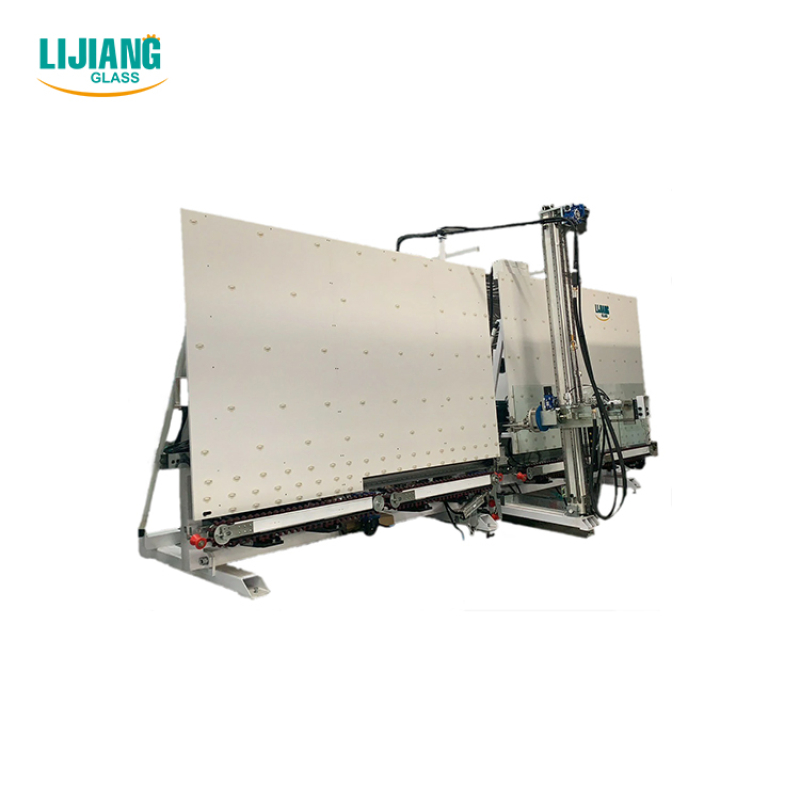

High-Efficiency LJTJ2025 Automatic Sealing Robot 2.5m Vertical Insulating Glass Laminating Machine Could be ConnectedProducts DescriptionAutomatic Vertical Insulating Glass Sealing RobotAutomatic insulating glass sealing robot can be connected to 2.5m vertical insulating glass glue machineProduct descriptionThe automatic vertical insulating glass sealing robot evenly smears the mixed sealant on the outer channel of the insulating glass through the servo mechanism, which is helpful to improve the sealing and bonding performance of the insulating glass.Advantages & FeaturesBenefits & Adv

Связаться сейчас

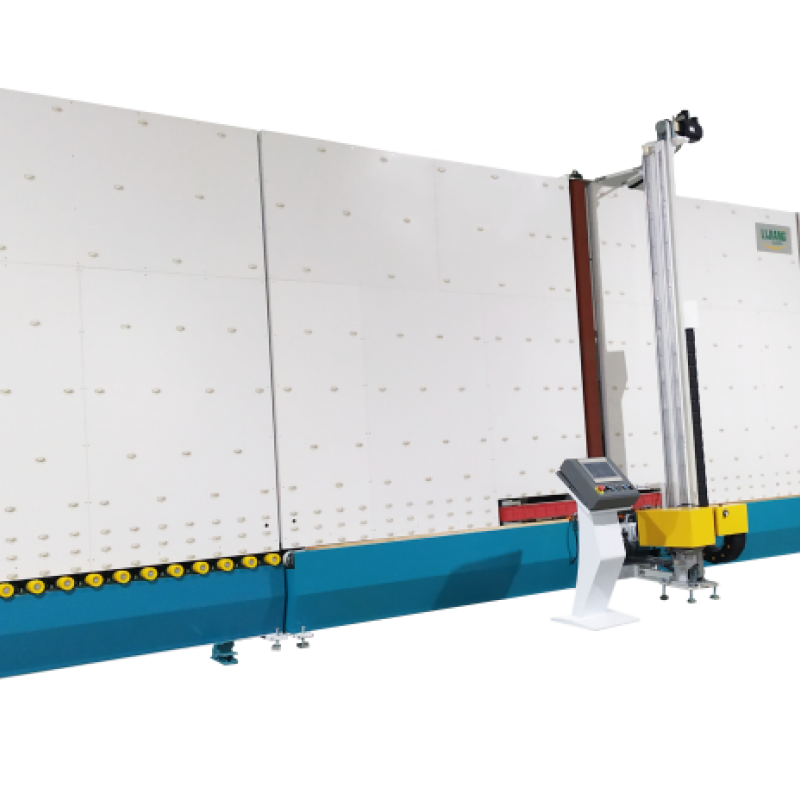

LJTJ2540 Automatic Vertical Insulating Glass Sealing Robot Could Making the Tempered glass is processed into Insulating GlassProduct DescriptionAutomatic Vertical Insulating Glass Sealing RobotJinan LIJIANG Glass Automatic Insulating Glass Sealant Sealing Robot Machine can apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.

Automatic Vertical Insulating Glass Sealing Robot Machine could apply the mixed sealant evenly to the outer channel of the insulating glass through the

Связаться сейчас

Automatic Sealing Robot Vertical Insulating Glass Laminating Machine Could be ConnectedProducts DescriptionAutomatic Vertical Insulating Glass Sealing RobotJinan LIJIANG Glass Automatic Insulating Glass Sealant Sealing Robot Machine can apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.Automatic Vertical Insulating Glass Sealing Robot Machine could apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the seali

Связаться сейчас

Specification of Insulating glass sealing robotModelLJTJ2540DVoltage Power380V 13KWAir Pressure0.5~0.7MpaExtruding pressure32MpaMax.Glass size2500*4000mmMin.Glass size400*300mmGlass thickness12~56mmWorking speed5~40m/minOverall dimension11000*1500*4500mmFunction and feature of Insulating glass sealing machine1.Insulating glass sealing machine is suitable for glass deep processing enterprise ,high automation, Reduce labor intensity, save manpower, improve production efficiency 2. Whole machine adopt man-machine touch screen interface,with memory function .

Связаться сейчас

LJTJ2025 Automatic Insulating Glass Coated Glass Double Component Sealing Robot MachineProduct DescriptionLJDM2545 Smart Vertical Edge Deleting MachineLJDM2545

smart vertical edge deleting machine is used to delete the edge film of

the Low-e glass. The glass edge deleting machine adopts an imported servo

control system, positioning accurately with smooth operation. High-quality grinding wheels are durable and can produce neat and beautiful

grinding cracks.

Связаться сейчас

Insulating Glass sealing robotTransfer sectionCoating detection mechanism, automatic detection of offline Low-e film Washing machine1. Using 6 pieces of soft brushes with 0.lmm soft hair. can wash low- glass2. New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak.

Связаться сейчас

PERFORMANCEJapan yaskawa servo manipulate machine, whole computerized and high-efficiencyComputerized reminiscence function, no need to enter parameters time and againAutomatically restore glass corners with scraper and curlerGadget has 4 sections, can maintain glassRobotically diploma glass duration and glue depth, adjust sealing velocityAdopt timing belt, smooth transfer and accurate roleEvery vehicle-feature is with manual operationCan coat double glass, fashioned glass, step glass, triple glassOne set of booster pump controls organizations of sealantsAutomatic timing glue discharging

Связаться сейчас

Insulated Double Glazed Glass Production Line seriesSizes :2000*2500mm2500* 3500mm3300* 7000mmFunctions :double glazing glasstriple glazing glassfour sides step glazing glassSpecial technology of IG Line :Making two pieces of IG units in once timeFilling argon gas onlineShaped glazing glassLow-e film glazing glassAir floating insulating glass lineMain Features of IG Line:• Adopt SIEMENS control system, keep stable performance• PLC control system, touch screen interface• Applicable to produce stepped IG, triple IG and shaped IG• Using servo to control system, modular function, superposition fun

Связаться сейчас

PERFORMANCEJapan yaskawa servo manage machine, complete automated and high-efficiencyComputerized memory function, no want to input parameters time and againAutomatically repair glass corners with scraper and curlerGadget has four sections, can keep glassRobotically degree glass length and glue depth, regulate sealing velocityAdopt timing belt, clean switch and correct roleEvery vehicle-characteristic is with guide operationCan coat double glass, shaped glass, step glass, triple glassOne set of booster pump controls corporations of sealantsAutomatic timing glue discharging featureThe glu

Связаться сейчас

Application Min & max glass sizes can be optionalAdopt eight servo motorsAdopt japan anchuan servo manipulate gadget with strong overall performanceRoutinely degree glass length, glue intensity and glue velocity with linear adjustmentAdopt timing belt to maintain clean carry with correct positionSpares are produced with high standardization and excessive precision, make sure the machine may be used with long-term operatingThe glass corners are full without air bubbles, smooth surface, no need to Full automatic and high-efficiency machineNew scraper design, especia

Связаться сейчас

PERFORMANCEJapan yaskawa servo control gadget, complete computerized and excessive-efficiencyAutomated reminiscence function, no want to enter parameters again and againRobotically restore glass corners with scraper and rollerMachine has four sections, can save glassAutomatically measure glass size and glue depth, adjust sealing speedAdopt timing belt, smooth transfer and accurate positionEvery auto-function is with manual operationCan coat double glass, shaped glass, step glass, triple glassOne set of booster pump controls two groups of sealantsAutomatic timing glue discharging functionThe gl

Связаться сейчас

• 01 transfer section01 transfer section is inclined vertical structure. The transmission roller is wear- resistant, acid and alkali polyamine grease roller, adopting the stepless frequency conversion speed regulation and the glass can run smoothly at the appropriate speed. The foot switch can according to the work situation start and stop transmission at any time.

Связаться сейчас

Application Min & max glass sizes may be non-obligatoryUndertake eight servo motorsUndertake japan anchuan servo manipulate gadget with stable overall performanceAutomatically degree glass length, glue depth and glue velocity with linear adjustmentAdopt timing belt to maintain smooth bring with accurate functionSpares are produced with high standardization and high precision, make sure the machine can be used with long-term operatingThe glass corners are full with out air bubbles, smooth floor, no need to Full automated and excessive-efficiency deviceNew scraper design, par

Связаться сейчас

1. Vertical Edge Deleting Machine UsageVertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system.

Связаться сейчас

Description of insulating glass production lineWhat does insulating glass production line do? Insulating glass production line is mainly for glass cleaning, plate pressing and inflation.

Связаться сейчас

Automatic Insulating Glass Sealant Sealing Robot Machine for Glass ProcessingLIJIANG Glass Automatic Insulating Glass Sealing Robot Machine can apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.Automatic Vertical Insulating Glass Sealing Machine could apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.The specific details of the sealing machine* Minimum a

Связаться сейчас

Glass vacuum lifter Glass lifting machine is used to loading and unloading glass for making insulating glass. The glass crane is vertical with arm and column, located in the front or the ending of the IG line and sealing robot. Glass suction crane is one of the vacuum spreaders, which is mainly used in glass production and processing and glass installation on construction site. The best equipment for handling glass is used in glass production and processing, insulating glass, laminated glass, vertical production line and horizontal manual gluing line. It can be used fo

Связаться сейчас

Automatic Insulating Glass Sealing Machine for glass ProcessingAutomatic insulting glass sealing robot is used for the second sealing procedure of the hollow glass.

Связаться сейчас

Automatic Butyl Extruder Machine used for Spreading Aluminum Spacer Frames Insulated Glass ProcessingProduct DescriptionAutomatic LJTB01 Butyl Extruder MachineThe

type of LJTB01 butyl extruder machine is used for spreading aluminum

spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machines

use a large electrical control panel which makes the operation easier. The conveyor of aluminum is controlled by a frequency converter,

and the speed can be adjusted from 0m/min to 47m/min, which has the

fastest speed in China.

Связаться сейчас

High Efficiency LJTJ2025 Automatic Sealing Robot 2.5m Vertical Insulating Glass Laminating Machine Could be ConnectedProducts DescriptionAutomatic Vertical Insulating Glass Sealing RobotLijiang Glass automatic insulating glass sealing robot evenly smears the mixed sealant on the outer channel of the insulating glass through the servo mechanism, which helps to improve the sealing and bonding performance of the insulating glass.Advantages & FeaturesMain Technical ParameterItem.Spec.Product nameVertical Insulating Glass Sealing Robot LJTJ2540Max.glass size2500*4000mmMin.glass size400mm*300mmG

Связаться сейчас

• Imported motor system to improve equipment efficiency• Imported sealant gun,stainless steel mixer• High pressure protect device• Anti-back flow control structure• Mixed rate detector can control the rate of two kinds of glueWorking air pressure0.3-0.6MPaSealant spreading pressure15-20MPaSealant volume4L/minDiameter of A/B sealant 570mm/280mmSealant spreading air pressure ratio50:1Mixed rate6:1-14:1Air supplyFlow 0.8m3/minAir pressure≥0.8MPaOverall dimension1100*950*1630mm

Связаться сейчас

1. What is the role of aluminum strip bending machine? Why do aluminum bars bend?Aluminum strip bending machine is mainly used for continuous bending of insulating glass aluminum strip. Aluminum strip bending can improve the sealing performance of insulating glass and its appearance is better2. What kinds of rigid insulating glass spacer are there?

Связаться сейчас

Main featureMain featureWhole machine adopt man-machine interface, the operation is more convenient and intuition with the simplified thinking design interface.The glass edge and corner is full without air bubbles, smooth surface, no need to pare the corner the condition that the glass are cut levelly and without dislocation after combined.High automation, high efficiency, suitable for glass deep processing enterprise to use.Can use two sets of independent sealant supply system( including the mixing device), two kinds of sealants switch in one-key operation easily.(optional)Servo control

Связаться сейчас

Main Product Structure 1 The two-component glue applicator mainly includes component A squeeze pump, component B squeeze pump, A glue pump travel assembly, B glue pump travel assembly, high-pressure plunger pump (proportional pump), ratio adjustment mechanism, mixed coating It is composed of a glue system, pneumatic control system and hydraulic control system.2 The squeezing pump of component A is driven by a hydraulic system, and the squeezing pump of component B is driven by a pneumatic system. The glue of component A is sucked in and increased to high pressure.

Связаться сейчас